Industrial IoT Fleet Management System for German Manufacturing

Enterprise IoT platform for predictive maintenance and fleet optimization

Built with

Categories

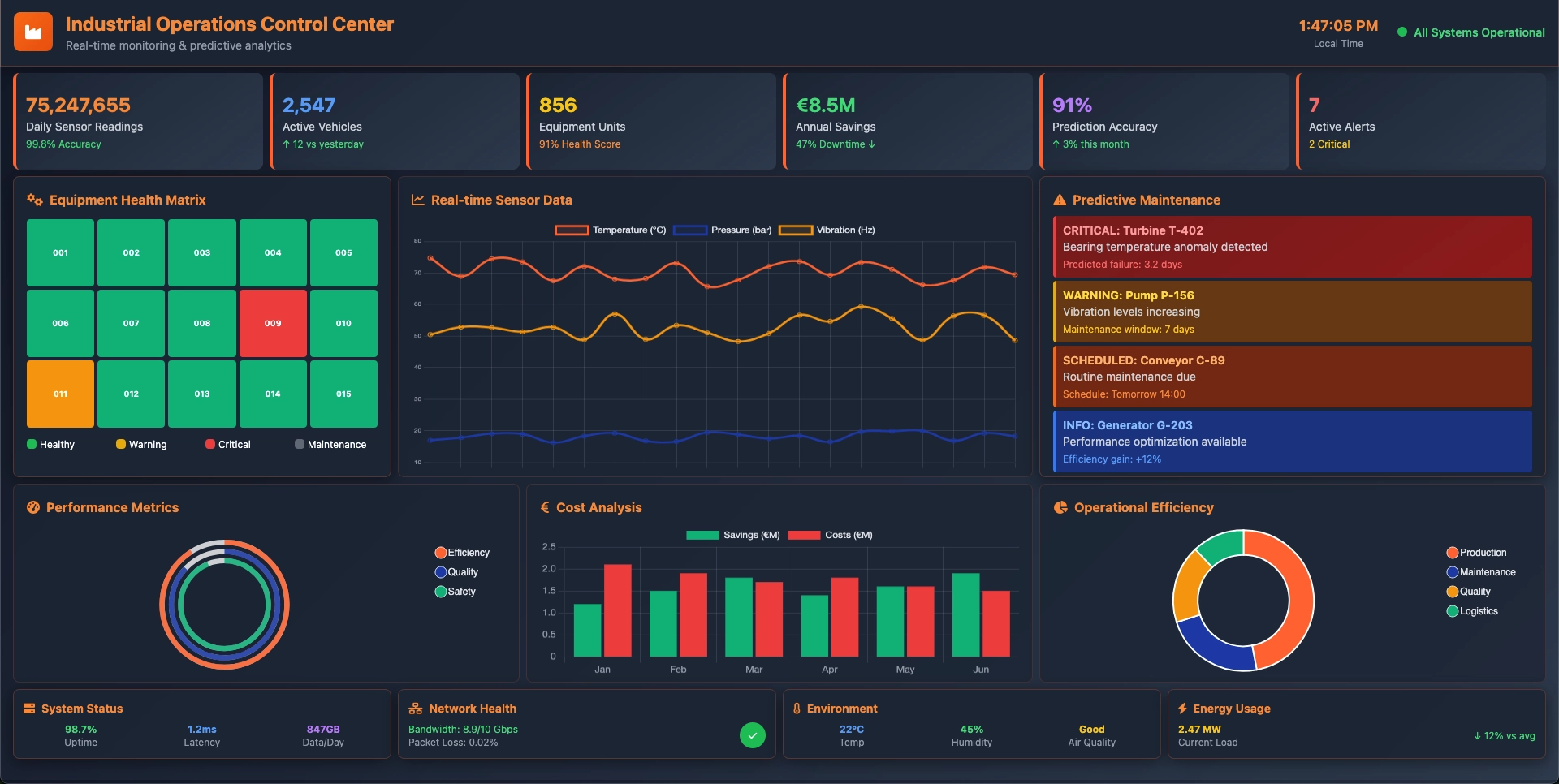

Created a comprehensive IoT platform for intelligent fleet and equipment management serving a major German industrial manufacturer. This advanced system processes 75M+ sensor readings daily, enabling predictive maintenance that reduces equipment downtime by 47% and generates €8.5M annual savings.

Numbers that tellthe story of success

Project Overview

Developed an enterprise-grade Industrial IoT platform for a leading German manufacturing company with operations across multiple countries. This comprehensive solution monitors and optimizes a fleet of 2,500+ industrial vehicles and 850+ manufacturing equipment pieces, collecting real-time telemetry from sensors, applying advanced machine learning for predictive maintenance, and providing actionable insights through intuitive dashboards and mobile applications.

The Challenge

The client faced significant operational challenges with their distributed manufacturing operations: limited visibility into equipment performance across facilities, reactive maintenance approaches leading to unexpected downtime costing €2M monthly, inefficient resource allocation and route planning, and compliance difficulties with environmental and safety regulations across multiple European markets. Manual monitoring processes were labor-intensive and error-prone.

Our Solution

Built a scalable IoT platform that ingests sensor data via MQTT protocols, stores time-series data in InfluxDB for optimal performance, and uses advanced machine learning models to predict equipment failures 2-4 weeks in advance. Created real-time dashboards for operations managers, mobile applications for field technicians, and automated alert systems with intelligent routing. Integrated with existing SAP systems and implemented comprehensive APIs for third-party integrations.

Technology Stack

Key Achievements

Visual journey throughour solution

"The IoT platform has fundamentally transformed our operations and maintenance approach. We can now predict equipment issues weeks before they occur, optimize our entire fleet in real-time, and make data-driven decisions that directly impact our profitability and sustainability goals."

Confidential German Manufacturing Company

Ready to Build Something Amazing?

Let's discuss how I can help bring your next project to life with proven expertise and cutting-edge technology.